[ad_1]

The semiconductor industry is notorious for its massive water consumption, with each chip requiring thousands of gallons of ultrapure water for production.

Ultrapure water (UPW) refers to water that has undergone purification to eliminate impurities, including fine particles and microorganisms, leaving behind only the fundamental hydrogen and oxygen molecules that make up H2O.

In response to the escalating demand for semiconductors, amplified by the ongoing global chip shortage, Samsung Semiconductor is planning to expand its production lines. One of the knock-on effects of this is that by 2030, the industrial water required for its facilities is projected to more than double from the current amount.

400 million liters

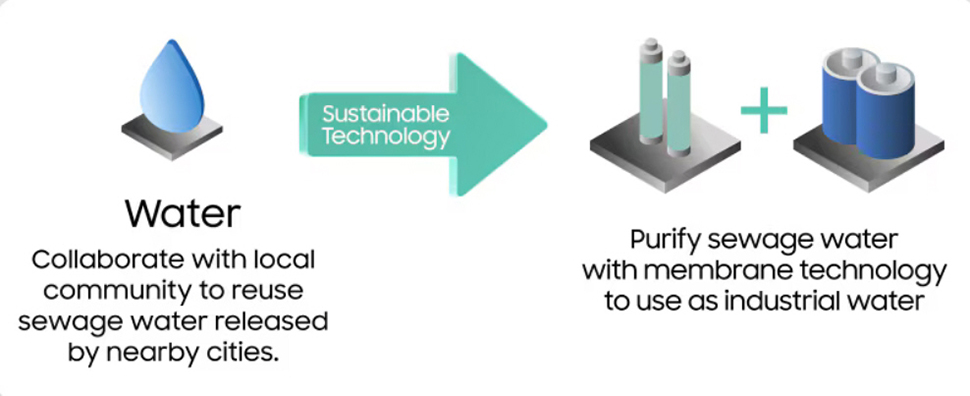

To address this demand, Samsung has announced plans to use wastewater to meet its enormous water needs.

The South Korean tech giant plans to purify and use an astonishing 400 million liters (105.668 million gallons) of wastewater daily for the manufacture of chips. The wastewater will be treated and purified to a standard safe for industrial use at the company’s Hwaseong plant.

Even minuscule impurities can impact chip production and quality, so the water will undergo multiple stages of filtration and purification to ensure it is completely free from any contaminants that could potentially harm the delicate semiconductor manufacturing process.

Samsung views this initiative as a significant step towards sustainable production. By using wastewater, the company is greatly reducing its reliance on freshwater sources, thereby contributing to water conservation efforts.

The move is expected to have a massive impact on the chip manufacturing industry, with other companies potentially following suit. It could set a new standard for sustainable practices in an industry that has long been under scrutiny for its environmental impact.

More from TechRadar Pro

[ad_2]

Source Article Link